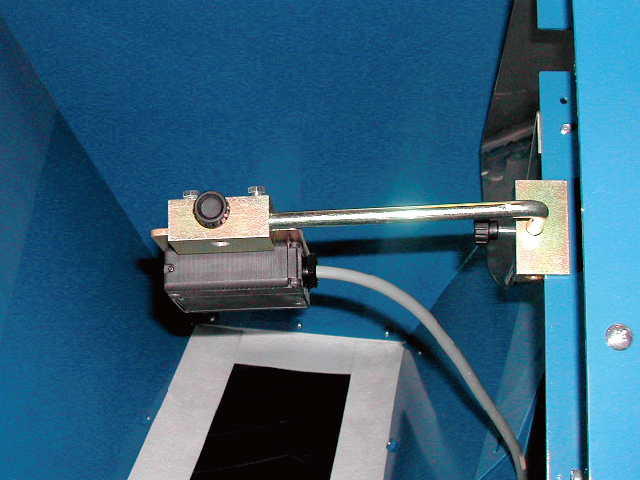

tray detection sensor

The tray detection sensor in the soil filling section discharges the soil only when the tray passes, so excess soil does not fall.

High performance potting machine

It has high processing capacity, excellent durability, and a large hopper capacity to improve work efficiency.

It is used on farms of large-scale producers and producers who are particular about performance.

It is also suitable for production farms that use heavy soil or a lot of soil.

It does not use a lift and is entirely belt driven, making it extremely durable.

| Model name | capacity(L) | Dimensions (width x depth x height)㎜ |

Capacitance |

|---|---|---|---|

| KYP-GT type 3-piece set | 50 | 2,200×3,400×1,730 | Three phase power supply 200V 0.96KW |

| KYS-GT1000 type hopper | 1,000 | 1,165×3,200×1,600 | Three phase power supply 200V 0.4 KW |

| KYS-GT2000 type hopper | 2,000 | 1,365×3,200×1,900 | Three phase power supply 200V 0.5 KW |

| KYS-GT3000 type hopper | 3,000 | 1,365×3,200×2,300 | Three phase power supply 200V 0.5 KW |

| custom hopper | Up to 6,000L | The raised type and length extended type have different specifications. |

※The combination of KYP-GT type and KYS hopper is collectively called KYP-GT1000 type to 3000 type.

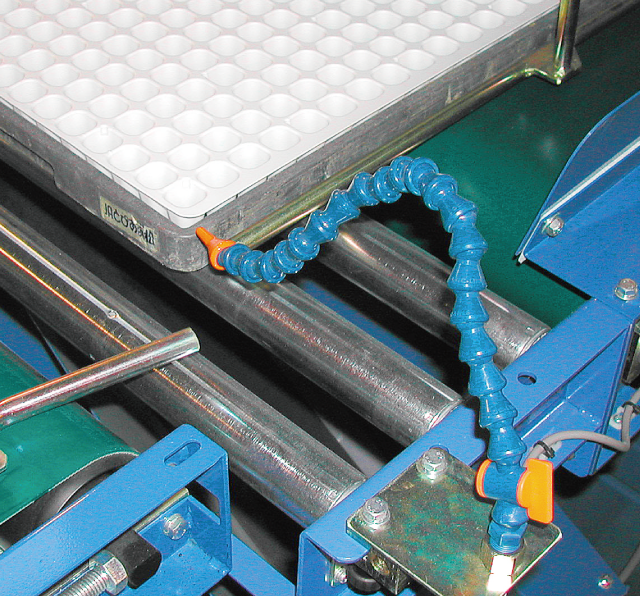

○vibration device/Used for plug trays and pots.

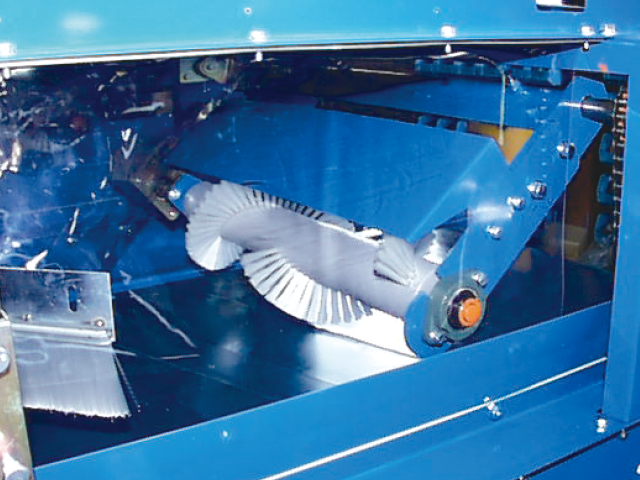

○rotating brush/This is an excellent brush with high cutting power and no sweeping back.

○spiral roller/The soil mixed on the back side of the belt does not stick to the rollers, so the belt is less likely to be damaged and cleaning is reduced.

○With soil discharge adjustment control

○With tray conveyor speed adjustment control

○Equipped with safety devices to prevent failures due to motor overload in each part

tray detection sensor

The tray detection sensor in the soil filling section discharges the soil only when the tray passes, so excess soil does not fall.

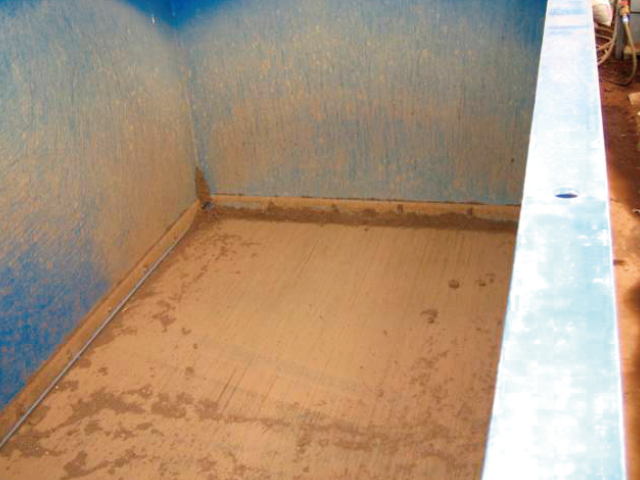

discharge chute

The soil filling section discharge chute suppresses the force of the soil falling, which prevents the pot from breaking and enables filling with a vapor phase.

Soil storage tank

Wide hopper that prevents bridging

Soil storage tank

All measures are taken to prevent slipping.

Enlarge the hopper on the supply conveyor. The hopper is equipped with a sensor that detects whether the hopper is full or has lost volume to control the amount of soil at a constant level.

This is a specification that connects the GT 3-piece set and mixer. Use the mixer as a hopper. The control on the mixer side is modified to an automatic control panel.

A large capacity hopper (6000L) is also available upon special order.

compaction roller

This is a 3-stage compaction roller.

Compaction is carried out at three different heights, minimizing the resistance and escape of the soil, resulting in stable compaction.

Earth leak prevention U-shaped fence

This is a fence to prevent loading into the hopper with a loader, etc.

Rotating brush inverter specifications

Ideal if you want to adjust brushing accuracy for each tray.

outlet side brush

Use a brush to remove soil that has accumulated around the edge of the tray.

outlet air brush

Use an airbrush to remove soil that has accumulated around the edge of the tray.